COMPANY NEWS

HOME - COMPANY NEWSRecommended! The explosion of intelligent industry, a new generation of high-precision bubble-free stickers, it is expected!

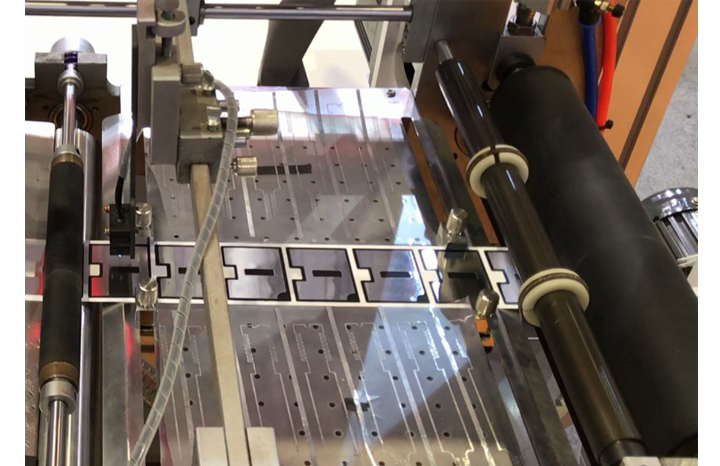

In the early stage of the development of the die-cutting industry, the application process was rarely applied in actual production. With the upgrading of customer product application fields and technologies, this demand has gradually emerged. The production cost of early materials and manual counterparts is still within the acceptable range of customers, but with the acceleration of social modernization, the previous production methods are obviously no longer Meet the actual needs.

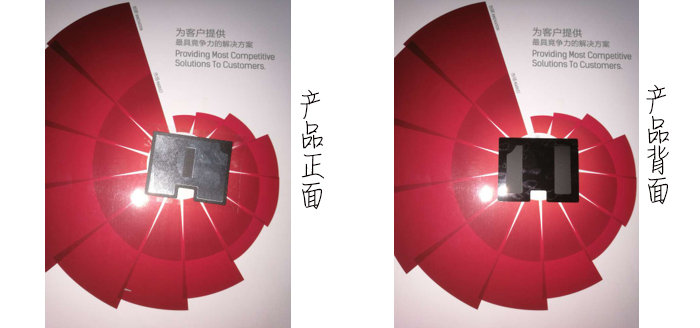

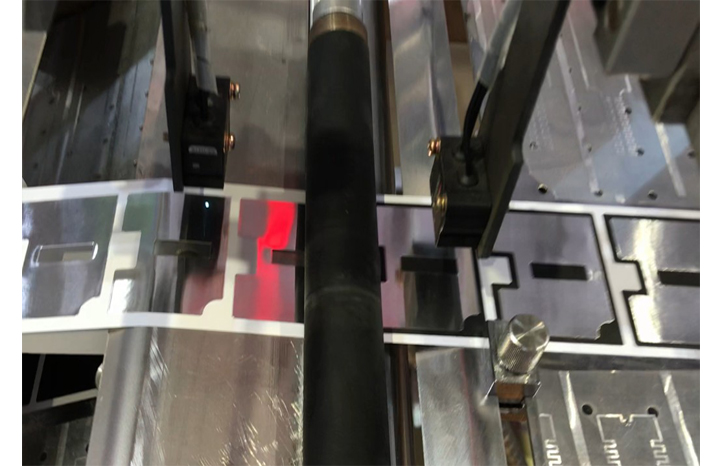

Most of the early use of manual visual matching, poor precision, bubbles, and low yield. Later, the process was upgraded and the fixture was applied. Although the accuracy problem was solved, the efficiency and bubble problem still became an insurmountable gap.

It is true that these stickers can be solved if they are rounded with a round knife, but they will face problems such as excessive equipment input costs and high mold opening costs.

Advantages highlight who I am

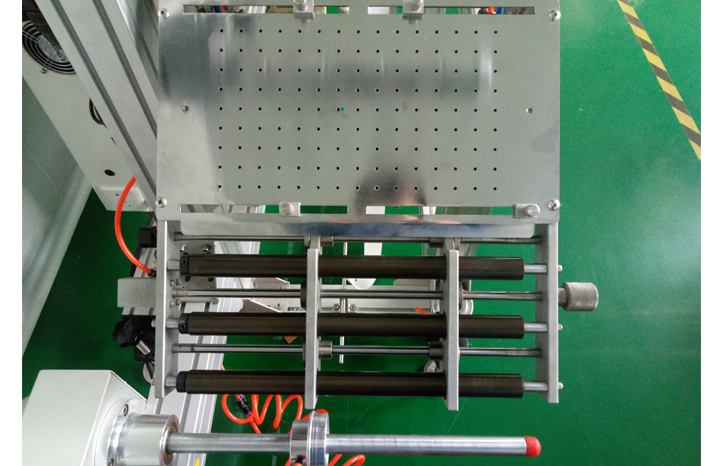

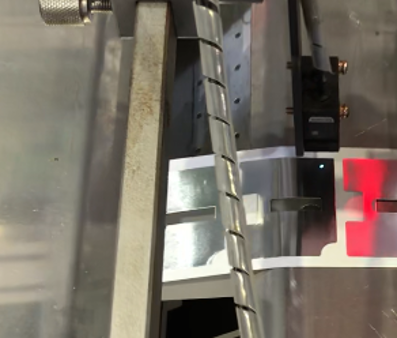

In the end, our company should invest huge energy and financial resources to develop automatic matching equipment according to the needs of customers. The main purpose is to solve the four problems raised by customers (1/efficiency 2/precision 3/yield 4/bubble). After the unremitting efforts of all the staff of our company, it is difficult to overcome the difficulties and finally present this precision machine to the customer.

At present, this precision matching machine of our company has the advantages of high fitting speed, high precision, high yield, no bubble, low cost and convenient operation.

HOT NEWS

- Professionalism comes from focus! The exhibition is perfect, we will continue to open! 2019-06-17

- Concentric, create greater glories! My company\\\'s 2018 annual ceremony and the end of the Thanksgiving feast ended successfully! 2019-01-22

- Our company participated in the 12th Shanghai APFE Exhibition 2016 2018-08-20

- The slashing market Deep planning - Schneider Electric supplier delegation visited our company to find a new article! 2018-11-03

- Recommended! The explosion of intelligent industry, a new generation of high-precision bubble-free stickers, it is expected! 2018-08-20

- 2008 China Suzhou Electronic Information Expo 2018-08-20

- Promote the Dragon Boat Festival culture and enhance cultural awareness 2018-08-20

- In 2012, our company participated in the China Suzhou Electronic Information Expo. 2018-08-20